When selecting temperature sensors for energy storage systems (ESS) and traction batteries (e.g., lithium-ion batteries used in electric vehicles), it is essential to consider several critical factors, as these sensors play a vital role in ensuring battery safety, performance, and longevity.

1. Temperature Range and Accuracy

- Operating Temperature Range: Typically, the operating range for both ESS and traction batteries is –40°C to +85°C, with extreme conditions (e.g., early-stage thermal runaway) potentially reaching +125°C. The sensor must cover the full expected operational and fault temperature range.

- Accuracy Requirement: Generally, ±0.5°C is acceptable; high-precision applications (e.g., BMS thermal management) may require ±0.1°C to ±0.3°C.

2. Response Time

- Thermal runaway can develop rapidly; therefore, sensors must offer fast response times (typically <10 seconds) to enable the Battery Management System (BMS) to take protective actions promptly.

- Response speed is influenced by packaging, mounting location, and thermal conduction paths.

3. Reliability and Long-Term Stability

- Sensors must operate reliably over extended periods under harsh conditions, including high vibration, humidity, and chemical exposure—especially in automotive applications.

- Prefer sensors with strong aging resistance and low drift, such as high-quality platinum RTDs (e.g., PT100/PT1000) or premium NTC thermistors.

4. Electrical Isolation and Safety

- Sensors must provide adequate electrical insulation to prevent interference or hazards from high-voltage battery strings.

- In high-voltage systems (e.g., 800V platforms), they should meet requirements for reinforced or double insulation, complying with relevant safety standards (e.g., IEC 60664, UL).

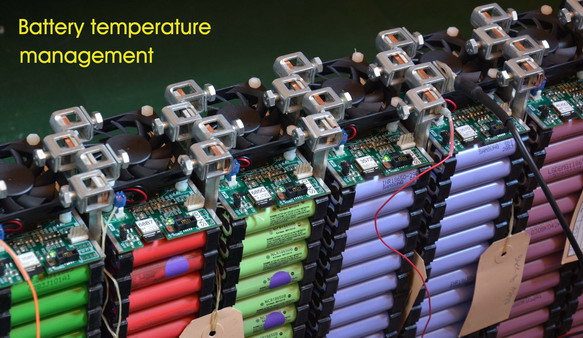

5. Size and Mounting Method

- Battery modules have limited space, so sensors should be compact (e.g., surface-mount, probe-type).

- Common mounting methods include:

- Surface mounting (attached to cell casing)

- Insertion into module gaps

- Soldering or adhesive bonding

- Ensure good thermal contact to avoid air gaps that cause measurement lag.

6. Signal Output and Compatibility

- Common sensor types:

- NTC Thermistors: Low cost, high sensitivity, but nonlinear—requiring calibration.

- PTC/RTDs (e.g., PT100): Excellent linearity and stability, but higher cost and larger size.

- Digital Temperature Sensors (e.g., DS18B20, TMP117): Direct digital output simplifies BMS design, but requires power and has limited voltage withstand capability.

- Must be compatible with the BMS’s ADC circuitry and software algorithms.

7. Certifications and Compliance

- Sensors must comply with relevant industry standards, such as:

- Automotive: AEC-Q200 (component reliability), ISO 26262 (functional safety)

- Energy Storage: UL 9540, IEC 62619, GB/T 36276

- Materials must meet environmental regulations like RoHS and REACH.

8. Redundancy and Multi-Point Temperature Monitoring

- For high-safety systems, distributed multi-point temperature sensing is recommended to avoid single-point failure.

- Critical locations (e.g., center of modules, near cell tabs, cooling plate interfaces) should be instrumented.

Typical Selection Recommendations:

|

Application Scenario |

Recommended Sensor Type |

Notes |

|

Low-cost ESS |

Epoxy/glass-encapsulated NTC thermistor |

Cost-effective, meets basic monitoring needs |

|

Premium EVs |

PT1000 or high-precision digital sensor |

High accuracy and long-term stability |

|

High-voltage platforms (>400V) |

Insulated NTC/PTC or fiber-optic sensors |

Enhanced electrical isolation |

|

Harsh environments (high temp/vibration) |

Ceramic-packaged NTC or platinum RTD |

Superior durability |

Summary:

When selecting temperature sensors, safety should be the top priority, balanced with accuracy, response speed, reliability, and ease of system integration. Selection should be based on specific factors such as battery chemistry (e.g., LFP, NCM), system voltage level, thermal management strategy (air/liquid cooling), and BMS architecture. Real-world testing under actual operating conditions is strongly recommended to validate performance.

For more tailored recommendations, please provide specific application parameters (e.g., battery type, voltage platform, available installation space).

Post time: Dec-01-2025