Thermistor History and introduction

NTC thermistor is an acronym for Negative Temperature Coefficient thermistor. Thermistor = Thermally sensitive resistor, it was discovered in 1833 by Michael Faraday, who was researching silver sulfide semiconductors, he noticed that the silver sulfides resistance decreased as the temperature increased, and then commercialized by Samuel Reuben in the 1930s, the scientists found that cuprous oxide and copper oxide also have negative temperature coefficient and performance, and they were successfully applied in the temperature compensation circuit of aviation instruments. Subsequently, due to the continuous development of transistor technology, great progress has been made in the research of thermistors, and in 1960, NTC thermistors were developed, it belongs to a large class of passive components.

NTC Thermistor is a kind of fine ceramic semiconductor thermal element which is sintered by several transition metal oxides, primarily of Mn(manganese), Ni(nickel), Co(cobalt) as raw materials, Mn3-xMxO4 (M=Ni, Cu, Fe, Co, etc.) is a material with significant Negative Temperature Coefficient (NTC), that is, the resistivity decreases exponentially with increasing temperature. Specifically, the resistivity and material constant vary with the proportion of material composition, sintering atmosphere, sintering temperature and structural state.

Because its resistance value changes precisely and predictably in response to small changes in body temperature (The degree of its resistance change depends on different parameter formulations), plus it's compact, stable and highly sensitive, it is widely used in temperature sensing devices for smart homes, medical probes, as well as in temperature control devices for household appliances, smartphones, etc., and in recent years has been used in large numbers in automobiles and new energy fields.

1. Basic Definitions and Working Principles

What is an NTC Thermistor?

■ Definition: A Negative Temperature Coefficient (NTC) thermistor is a semiconductor ceramic component whose resistance decreases exponentially as temperature increases. It is widely used for temperature measurement, temperature compensation, and inrush current suppression.

■ Working Principle: Made from transition metal oxides (e.g., mangan ese, cobalt, nickel), changes in temperature alter the carrier concentration within the material, resulting in a change in resistance.

Comparison of Temperature Sensor Types

| Type | Principle | Advantages | Disadvantages |

|---|---|---|---|

| NTC | Resistance varies with temperature | High sensitivity, low cost | Non-linear output |

| RTD | Metal resistance varies with temperature | High accuracy, good linearity | High cost, slow response |

| Thermocouple | Thermoelectric effect (voltage generated by temperature difference) | Wide temperature range (-200°C to 1800°C) | Requires cold junction compensation, weak signal |

| Digital Temperature Sensor | Converts temperature to digital output | Easy integration with microcontrollers, high precision | Limited temperature range, higher cost than NTC |

| LPTC (Linear PTC) | Resistance increases linearly with temperature | Simple linear output, good for over-temperature protection | Limited sensitivity, narrower application scope |

2. Key Performance Parameters and Terminology

Core Parameters

■ Nominal Resistance (R25):

The zero-power resistance at 25°C, commonly ranging from 1kΩ to 100kΩ. XIXITRONICS can be customized to meet 0.5~5000kΩ

■ B Value (Thermal Index):

Definition: B = (T1·T2)/(T2-T1) · ln(R1/R2), indicating the sensitivity of resistance to temperature changes (unit: K).

Common B value range: 3000K to 4600K (e.g., B25/85=3950K)

XIXITRONICS can be customized to meet 2500~5000K

■ Accuracy (Tolerance):

Resistance value deviation (e.g., ±1%, ±3%) and temperature measurement accuracy (e.g., ±0.5°C).

XIXITRONICS can be customized to meet ±0.2℃ in the range of 0℃to 70℃, the highest accuracy can reach 0.05℃.

■ Dissipation Factor (δ):

The parameter indicating self-heating effects, measured in mW/°C (lower values mean less self-heating).

■ Time Constant (τ):

The time required for the thermistor to respond to 63.2% of a temperature change (e.g., 5 seconds in water, 20 seconds in air).

Technical Terms

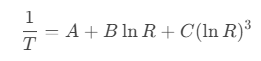

■ Steinhart-Hart Equation:

A mathematical model describing the resistance-temperature relationship of NTC thermistors:

(T: Absolute temperature, R: Resistance, A/B/C: Constants)

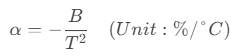

■ α (Temperature Coefficient):

The rate of resistance change per unit temperature change:

■ R-T Table (Resistance-Temperature Table):

A reference table showing standard resistance values at different temperatures, used for calibration or circuit design.

3. Typical Applications of NTC Thermistors

Application Fields

1. Temperature Measurement:

o Home appliances (air conditioners, refrigerators), industrial equipment, automotive (battery pack/motor temperature monitoring).

2. Temperature Compensation:

o Compensating for temperature drift in other electronic components (e.g., crystal oscillators, LEDs).

3. Inrush Current Suppression:

o Utilizing the high cold resistance to limit inrush current during power startup.

Circuit Design Examples

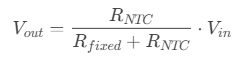

• Voltage Divider Circuit:

(Temperature is calculated by reading the voltage via an ADC.)

• Linearization Methods:

Adding fixed resistors in series/parallel to optimize the non-linear output of NTC (include reference circuit diagrams).

4. Technical Resources and Tools

Free Resources

• Datasheets: Include detailed parameters, dimensions, and test conditions.

• R-T Table Excel ( PDF ) Template: Allows customers to quickly look up temperature-resistance values.

o Design Considerations for NTC in Lithium Battery Temperature Protection

o Improving NTC Temperature Measurement Accuracy through Software Calibration

Online Tools

• B Value Calculator: Input T1/R1 and T2/R2 to calculate the B value.

• Temperature Conversion Tool: Input resistance to get the corresponding temperature (supports Steinhart-Hart equation).

5. Design Tips (For Engineers)

• Avoid Self-Heating Errors: Ensure the operating current is below the maximum specified in the datasheet (e.g., 10μA).

• Environmental Protection: For humid or corrosive environments, use glass-encapsulated or epoxy-coated NTCs.

• Calibration Recommendations: Improve system accuracy by performing a two-point calibration (e.g., 0°C and 100°C).

6. Frequently Asked Questions (FAQ)

1. Q: What is the difference between NTC and PTC thermistors?

o A: PTC (Positive Temperature Coefficient) thermistors increase resistance with temperature and are commonly used for overcurrent protection, while NTC thermistors are used for temperature measurement and compensation.

2. Q: How to choose the right B value?

o A: High B values (e.g., B25/85=4700K) offer higher sensitivity and are suitable for narrow temperature ranges, while low B values (e.g., B25/50=3435K) are better for wide temperature ranges.

3. Q: Does wire length affect measurement accuracy?

o A: Yes, long wires introduce additional resistance, which can be compensated for using a 3-wire or 4-wire connection method.

Our prices are more competitive compared to those in Europe, America, Japan and South Korea, they are at a medium level in China.

From the perspective of cost-effectiveness, the thermistors and temperature sensors produced by our company are the best choice for you.

For regular parameters of thermistors or chips, we usually have stock and can deliver them within 3 days.

Special chips with customized parameters require a development and production cycle of 21 days.

For ordinary sensors, the first production run requires 100 to 1000 units will takes 7-15 days. The second production run of 10,000 units takes 7 days.

Special or customized sensors will vary depending on the procurement cycle of the raw materials

Generally, we accept bank transfers. For smaller amounts, we also accept Western Union or PayPal.

In most cases, we are 100% TT in advance. For long-term cooperative customers and repeat orders, we can negotiate to accept 30 Net DAY.

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.