Evaluating the quality of an NTC (Negative Temperature Coefficient) thermistor chip and determining its performance hinges on several key dimensions and factors:

1. Core Materials & Manufacturing Process (Determines Fundamental Performance & Long-Term Stability)

- Ceramic Body Material:

- High Quality: Uses high-purity, uniformly grained, and optimally formulated mixtures of metal oxides (e.g., oxides of Mn, Ni, Co, Fe, Cu). Reliable material sources with high batch-to-batch consistency.

- Low Quality: Low-purity materials, high impurities, uneven grain size, unstable formulation. Leads to high dispersion in resistance (R) and B-value, poor stability.

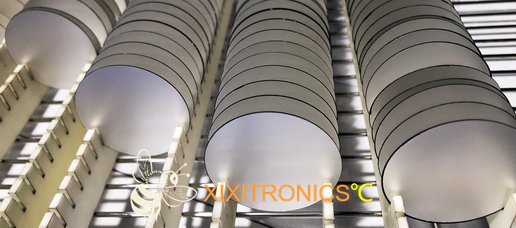

- Sintering Process:

- High Quality: Precise control of sintering temperature profile, atmosphere (usually air or specific gas), and time. Ensures a dense ceramic body with uniform grain structure and stability. Crucial for good electrical properties and long-term stability.

- Low Quality: Poorly controlled sintering process, significant temperature fluctuations, insufficient or excessive time. Results in porous ceramic, abnormal grain growth, or internal stress, leading to resistance drift, cracking, or failure.

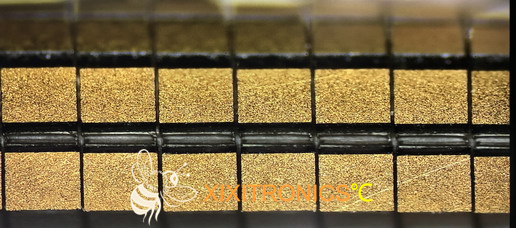

- Electrode Material & Process:

- High Quality: Uses electrode materials with strong adhesion, good oxidation resistance, and high conductivity (e.g., silver paste, silver-palladium paste). Precise electrode coating/firing process ensures good ohmic contact, low and stable contact resistance, and high reliability.

- Low Quality: Poor electrode material (prone to oxidation, weak adhesion), uneven coating, or improper firing. Causes poor contact, high/unstable contact resistance, or even electrode detachment.

2. Key Electrical Parameters & Accuracy (Directly Impacts Measurement Accuracy & Interchangeability)

- Nominal Resistance (R25) Tolerance:

- High Quality: Small tolerance on the nominal resistance value at a specific temperature (usually 25°C). Tighter tolerances (e.g., ±1%, ±2%, ±3%, ±5%) mean smaller initial measurement error and better interchangeability.

- Low Quality: Large R25 tolerance (e.g., ±10% or higher). Means significant resistance variation between chips at room temperature, poor interchangeability, large initial error.

- B-Value Tolerance:

- High Quality: Small tolerance on the B-value (material constant, reflecting sensitivity of resistance change with temperature). Tighter tolerances (e.g., ±0.5%, ±1%, ±2%) are critical for accuracy, especially at temperatures far from 25°C. High-precision applications demand strict B-value tolerance.

- Low Quality: Large B-value tolerance (e.g., ±3% or higher). Causes inconsistent temperature-resistance curves, significantly increased error away from 25°C, and large variation between chips.

- R25/B-Value Matching Consistency:

- High Quality: High consistency in R25 and B-value within a single batch. Essential for applications using multiple NTCs for temperature compensation or differential measurement.

- Low Quality: Poor within-batch consistency, making matching difficult and requiring extra screening, increasing cost and complexity.

3. Stability & Reliability (Determines Long-Term Performance)

- Long-Term Stability / Aging Characteristics:

- High Quality: Minimal resistance drift after prolonged operation under rated conditions (temperature, humidity, load current). Measured by resistance change rate (ΔR/R) after high-temperature aging (e.g., 125°C or 150°C for 1000 hours). High-quality NTCs have very low drift rates (e.g., <0.5% or lower).

- Low Quality: Significant drift after aging (e.g., >1% or several percent). Measurement accuracy degrades over time.

- Resistance to Thermal Cycling:

- High Quality: Withstands multiple severe temperature changes (thermal shock) without significant permanent resistance change or cracking. Evaluated by resistance change after specified extreme temperature cycles (e.g., -55°C to +150°C).

- Low Quality: Exhibits irreversible drift or physical damage after few thermal cycles.

- Moisture Resistance:

- High Quality: Dense chip structure, good encapsulation (even bare chips should have inherently moisture-resistant ceramic). Stable resistance in high humidity. Verifiable via damp heat testing (e.g., 85°C/85% RH).

- Low Quality: Prone to moisture absorption, causing resistance drift or failure, especially in poorly encapsulated applications.

4. Thermal Performance Parameters (Affect Response Speed & Suitability for Applications)

- Dissipation Constant (δ):

- High Quality: Clearly specified value meeting application needs. Requires a small δ for precision temperature sensing to minimize self-heating effects.

- Low Quality: Poorly specified or non-compliant. Excessive δ causes significant self-heating under measurement current, introducing error.

- Thermal Time Constant (τ):

- High Quality: Clearly specified value meeting application response speed requirements. Requires a small τ for applications needing fast temperature tracking.

- Low Quality: Slow response (large τ), unable to follow temperature changes.

5. Packaging & Mechanical Characteristics (Affect Ease of Use & Environmental Suitability)

- Packaging Quality (for encapsulated NTCs):

- High Quality: Packaging material (e.g., epoxy, glass, silicone) is temperature/humidity resistant, has good insulation, bonds strongly to chip/leads, and is well-sealed (no bubbles/cracks). Robust leads.

- Low Quality: Poor packaging material, prone to aging/cracking, poor sealing allowing moisture ingress, weak leads.

- Mechanical Strength (Bare Chips):

- High Quality: Ceramic body has sufficient mechanical strength, resistant to breakage.

- Low Quality: Brittle material, prone to cracking during handling or use.

6. Manufacturer & Datasheet

- Manufacturer Reputation & Qualifications:

- High Quality: Reputable brand or reliable specialist manufacturer with strict quality control (e.g., ISO certified), providing detailed and accurate datasheets.

- Low Quality: Unverified small suppliers, vague, incomplete, or exaggerated datasheets.

- Datasheet Completeness & Rigor:

- High Quality: Provides detailed specifications for all key parameters (R25 tol., B-value tol., B-value temp. range, δ, τ, operating temp. range, max power, aging test conditions/results, thermal cycle test conditions/results, etc.). Clear, unambiguous labeling.

- Low Quality: Missing parameters (especially B-value accuracy & stability), vague test conditions, only best-case parameters without tolerance ranges.

Summary: How to Distinguish Quality? What to Look For?

1. Focus on Core Parameter Accuracy: Prioritize R25 tolerance and B-value tolerance. Chips with tighter tolerances (higher accuracy) are generally higher quality (and costlier). Choose based on your application's accuracy needs.

2. Examine Stability Specifications: Request aging test data (e.g., ΔR/R after 125°C/1000h) and thermal cycling test data from suppliers. Lower drift is better. This is key to differentiating standard from high-quality chips.

3. Verify Thermal Parameters: Ensure the dissipation constant (δ) and thermal time constant (τ) meet application requirements (Will self-heating be significant? Is response speed adequate?).

4. Assess Datasheet Quality: A complete, clear datasheet with all key parameters, tolerances, and test conditions typically indicates a professional, reliable manufacturer. Be wary of products with missing or vague specs.

5. Consider Manufacturer Background: Choose reputable, certified manufacturers. Established brands usually invest more in materials, processes, and QC.

6. Check Packaging Quality (if applicable): Inspect for integrity, absence of defects, and lead robustness.

7. Conduct Actual Testing (Crucial): For critical applications, test samples yourself, especially performing accelerated aging and thermal cycling. Comparing parameters before and after testing is the most direct verification method.

In short: High-quality NTC chips offer high accuracy (tight R25 and B-value tolerances), high stability (minimal drift after aging), have comprehensive and reliable datasheets, and come from reputable manufacturers. Do not judge solely on nominal resistance value or price; pay close attention to critical performance indicators like B-value accuracy and long-term stability.

Post time: Aug-12-2025